Chapter 1

Globalization in the rearview mirror

Most industrial companies are now investing to defend against interconnected geopolitical threats.

This shift in the global operating environment is particularly jarring because we are emerging from a long cycle in which relative geopolitical and economic stability felt all but assured.

In the nearly three-decade period following the fall of the Berlin Wall, manufacturers experienced expanded opportunities to crack vast new markets, dramatically lower production costs, and reap the rewards of innovation on an entirely new scale. Risks from smaller-scale political tensions and market fluctuations paled in comparison to the huge upside stemming from the enlarged global playing field.

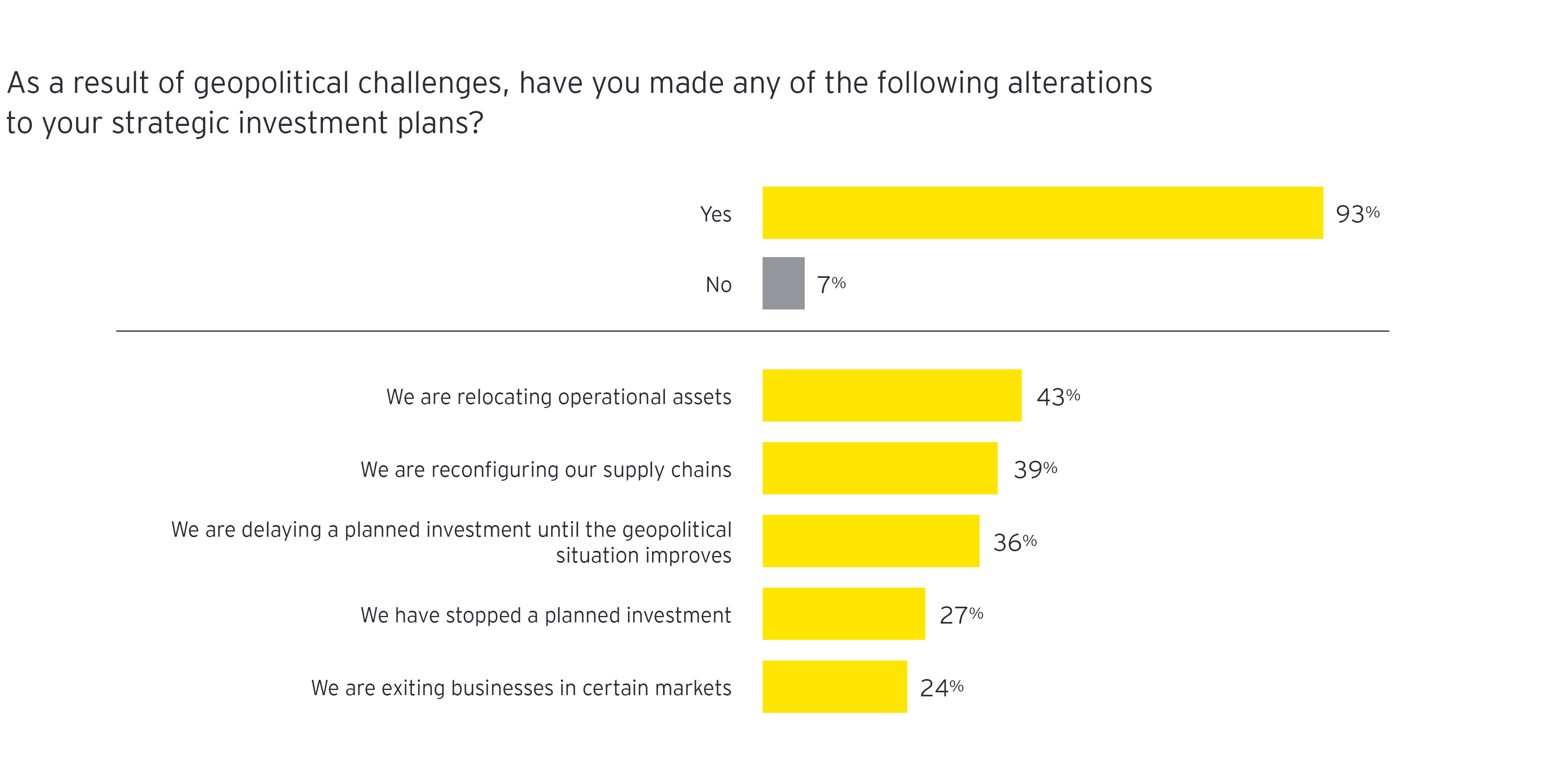

But that was then. Today, most industrial companies are investing to defend against significant and interconnected geopolitical threats. In the EY CEO Outlook Pulse — October 2022, 93% of industrial respondents said they altered strategic investment plans as a result of geopolitical challenges, spending to boost resilience and improve defensive positioning. Of those who have failed to complete or canceled a planned acquisition in the past 12 months (93%), nearly a quarter blamed geopolitical tensions and uncertainty.

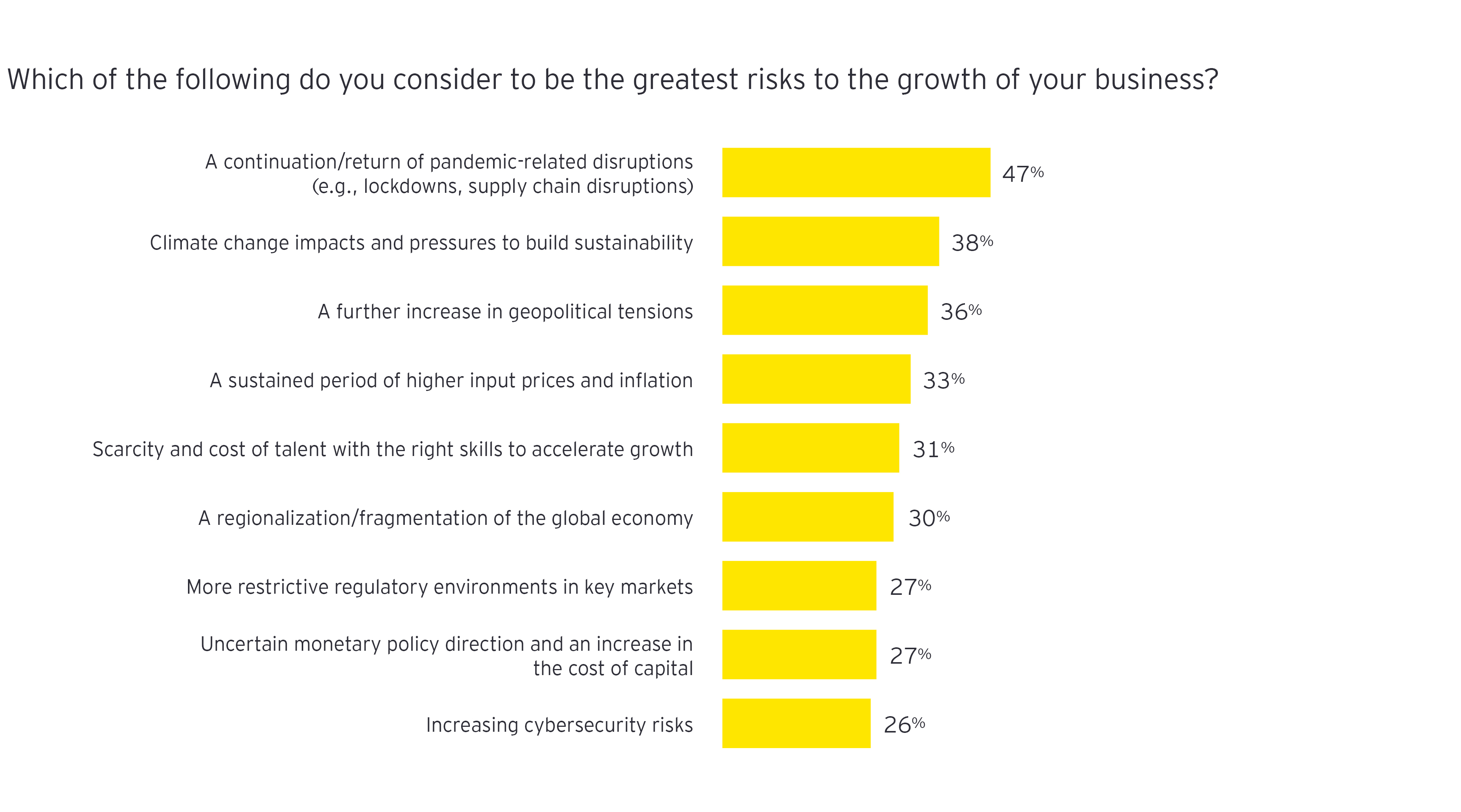

Looking forward, 36% cited increasing geopolitical tensions as a top-three risk to growth. Another overtly geopolitical risk, regionalization/fragmentation of the global economy, was not far behind with 30% — while all the remaining factors directly or indirectly intersect with government activity and the nature of the global operating environment.

Adjusting strategies for an array of geopolitical variables is no small challenge, underscored by the scale of events few anticipated — a global pandemic, war in Ukraine and massive, worldwide supply chain shortages. Decision-makers could rationalize treating the future geopolitical state as a “known unknown” to be acknowledged but not meaningfully analyzed.

However, the most successful leaders will lean in and proactively take measures to strengthen their position, instead of simply disengaging with the excuse that there are too many unknowns. The essential tool creating a strong strategy is comprehensive scenario planning: imagining in detail a range of possible geopolitical futures and their corresponding risks and opportunities.

Chapter 2

Four geopolitical scenarios and implications for manufacturers

Global operating environments could be affected depending on the events direction.

The EY CEO Imperative series recently examined four plausible geopolitical futures that could emerge in the next five years. These possible scenarios illustrate how the global operating environment is affected by changes in international relations, trade and broader economic policies.

They are ranked below from most to least restrictive environment for international business:

1. Self-reliance reigns

A new era of isolationism diminishes international trade. This significantly reduces growth for the vast majority of industrial firms, while creating opportunities for others that can help deliver autonomy for strategic goods and materials. Companies would be forced to adopt domestic-focused growth strategies, pursuing vertical integration or moving into adjacent industries.

2. Cold War II

Like the original Cold War, the sequel would force companies to trade within distinct economic blocs along with significant onshoring or nearshoring of operations and supply chains. Certain sectors, such as defense, would thrive, while most would face diminished market opportunity and less access to talent.

3. Friends first

This future would also restrict global trade and investment, although manufacturers would have a number of regional trade blocs and other “friendly” clubs of countries in which to operate. However, protectionism, sustainability concerns and “friend-shoring” add costs and complexity. Friction between the US/EU and Chinese trading networks creates ongoing uncertainty.

4. Globalization lite

This outcome would look much like the one we knew a few years ago, albeit modestly less open. Strong global growth and limited tensions would stimulate investment and M&A, aided by an efficient talent market. For most manufacturing businesses, this is by far the most favorable scenario — but, unfortunately, it also appears to be the least likely.

A continued shift away from the Globalization lite scenario would test industrial companies’ agility and resilience. Futures resembling Cold War II or Self-reliance reigns could render the global markets and operations of multinational manufacturers far less accessible or even inaccessible, raising strategic questions of the highest order.

Chapter 3

Making sense of the future: framework for geopolitical scenarios

Manufacturers should consider a range of future states and implement new levels of agility.

Each geopolitical scenario would affect individual manufacturers differently, though in all cases their impacts would be enterprise-wide. As such, we use a broad analytical framework to evaluate them, focusing on nine dimensions:

Key dimensions for geopolitical scenario analysis

To illustrate the varied impact across different sectors, several critical dimensions that emerged from our analysis of both the aerospace and defense sector and the chemicals and advanced materials sector are highlighted below.

Selected key dimensions: Aerospace and defense

- Customer and revenue

Commercial aerospace players’ reliance on China for growth emerges as a risk area in the more extreme scenarios. Boeing’s latest outlook of October 2022 forecasts that the Chinese market will account for more than 20% of global aircraft deliveries over the next two decades. If Western suppliers face reduced market access or are cut off completely, firms that have more aggressively diversified and added new sources of value will be best positioned.

In contrast, scenarios with heightened geopolitical tensions will naturally benefit defense players. Cold War II would reward larger firms with the scale and existing international relationships to win the next wave of franchise programs. These firms would also thrive in self-reliance reigns, though smaller regional or in-country champions would experience unparalleled demand, as domestic self-sufficiency becomes a key priority for many countries. Irrespective of size, companies that have prioritized innovation in high-value capability areas (e.g., autonomous systems and advanced analytics or machine learning) will be best-positioned to ride the rising budgetary tides.

- Human capital

Both commercial aerospace and defense firms currently struggle with skilled labor shortages, particularly due to technology sector competition. In more extreme scenarios, reduced international mobility creates additional inefficiencies in the talent market. Despite government policy support increasing along with geopolitical tensions, defense companies in particular will still struggle to fill seats due to their need for expertise in newer and advanced technologies as well as security clearances.

Given these challenges, companies in both sectors should invest in their cultures and overall value proposition — looking beyond compensation to broadly defined benefits and post-pandemic flexible ways of working. Those that also effectively deploy technology to transform knowledge capture and skill development (e.g., augmented reality or virtual reality for accelerated training) and retention (e.g., data analytics to assess departure risk) will increase their competitive edge.

Selected key dimensions: Chemicals and advanced materials

- Operations and supply chain

The US/EU decoupling from China, which is anticipated in more extreme scenarios, would restructure the global chemicals industry. Product and export costs would rise as American, European and Japanese players onshore or “friend-shore” production, particularly for specialty materials. An isolated China would be challenged to drive demand in less-attractive destination markets. Increased tariffs globally would further drive companies to align supply with new market blocs, adding costs along the value chain in a lower-growth or recessionary economic environment.

In addition, a prolonged war in Ukraine would seriously disrupt petrochemical feedstock supply and destroy destination demand for EU manufacturers. Production of certain plastics and fertilizers would shift to the natural gas-rich US and Middle East. Weaker demand for EU-manufactured chemicals in Russia and Central Europe would increase export pressures, escalating regional price competition in a lower-demand environment.

Successful firms will especially need to accelerate productivity improvement by investing in digital supply chain, manufacturing and automation.

- Sustainability

More challenging geopolitical scenarios would reduce the overall pace of sustainability investment by chemicals players. Imperatives such as plastic waste reduction and recycling, government incentives and mandates, and electric vehicle transition would remain, but the drive to achieve sustainability targets would likely suffer globally as firms grapple with existential threats.

However, regional differences would likely arise based on country or bloc-specific resource constraints. Oil and energy-intensive chemicals (i.e., petrochemicals, plastics, fertilizers) would be tightly controlled and face export tariffs. In some regions, agriculture could play a greater role as a domestic source of renewable energy and alternative feedstocks.

Chapter 4

Five 'no regrets' moves manufacturers should make now

Now is the time to identify and implement strategic actions to reduce risk, no matter what the future holds.

Industrial leaders should assess the impact of these and other geopolitical scenarios on their own businesses. Then they must identify and implement strategic actions to not only reduce risk, but to thrive — regardless of which scenario the actual future most closely resembles. Each firm will have its own priorities, though EY teams believe the following foundational “no regrets” moves are critical for every manufacturer:

1. Enhance scenario-planning capabilities

All firms should actively embed geopolitical scenario development in all corporate strategy exercises and focus on identifying opportunities (customers, pricing, M&A) as well as risks. However, this is particularly critical in the industrial sector, where output is often high value, large-scale, complex and resource-intensive.

Scenario development should include identification of early warning indicators — election outcomes, policy rhetoric, military spending, etc. — that can be monitored for signs of which future may be emerging.

2. Invest in the business of customer experience

Industrial firms need to place the customer at the beginning of their value chains — not the end — by aligning customer strategies and priority areas with their own. If geopolitical developments generate rapid demand shifts and operational complexities for customers, engagement platforms that increase the ease of doing business and transparency will be key differentiators.

Frictionless, consumer-style e-commerce platforms will be critical for commodities. Custom products and systems will require digital platforms that enable intelligent search, consultative selling and visibility of pricing and availability to drive increased customer revenues and reduced cost-to-serve.

3. Drive operational resiliency

The complexity of many industrial businesses means there are many potential avenues for increasing resiliency. They may include avoiding single sources of supply, increasing sustainability and circularity, establishing their own renewable power generation infrastructure, and harnessing data to optimize working capital and pricing execution. Firms should prioritize cost-efficient actions to maximize agility in the face of large-scale supply-and-demand fluctuations.

4. Create a differentiated employee value proposition

Geopolitical upheaval and uncertainty will only worsen the industrial sector’s existing recruiting and retention issues. Leaders must build a work culture that creates employee connections while also using data-driven insights into compensation, benefits and new ways of working to prevent this most critical resource from being depleted over time — or overnight.

5. Accelerate digitalization

Digitalization does not always rise to the top of manufacturers’ priority investments lists, but it is essential for long-term cost and market advantages. It also underpins numerous aspects of our other “no regrets” moves. Frictionless online selling, real-time supply chain monitoring, digital twin-enabled assessments of production and ecosystem vulnerabilities — without comprehensive digital transformation, none of these are possible.

In some geopolitical scenarios, your future may also depend on having selected digital suppliers and partners who will not suddenly be cut off by sanctions or other government intervention — so it is critical to assess potential new relationships as part of regular scenario planning exercises.

Conclusion

In the less volatile world of the not-so distant past, increasing globalization provided a relatively straightforward growth playbook. Now, that unique political and economic environment is gone. Going forward, successfully defending against emerging threats and seizing new opportunities will depend on highly vigilant observation of changing conditions, adaptive corporate strategies, and more agile and resilient operations.

Thank you to Chris Cardinal, EY Americas Chemicals and Advanced Materials Executive Director; Joe Gaynor, EY-Parthenon Advanced Manufacturing and Mobility Global Development Lead; and Mayukh Chaudhuri, EY Americas Advanced Manufacturing and Mobility, Strategy and Transactions Manager for contributing to this article.

Related articles

Summary

Industrial firms are exposed to many increasing geopolitical risks. Manufacturers should proactively consider different future states and implement agility in their strategies and operations.